Case Studies

Network schematics

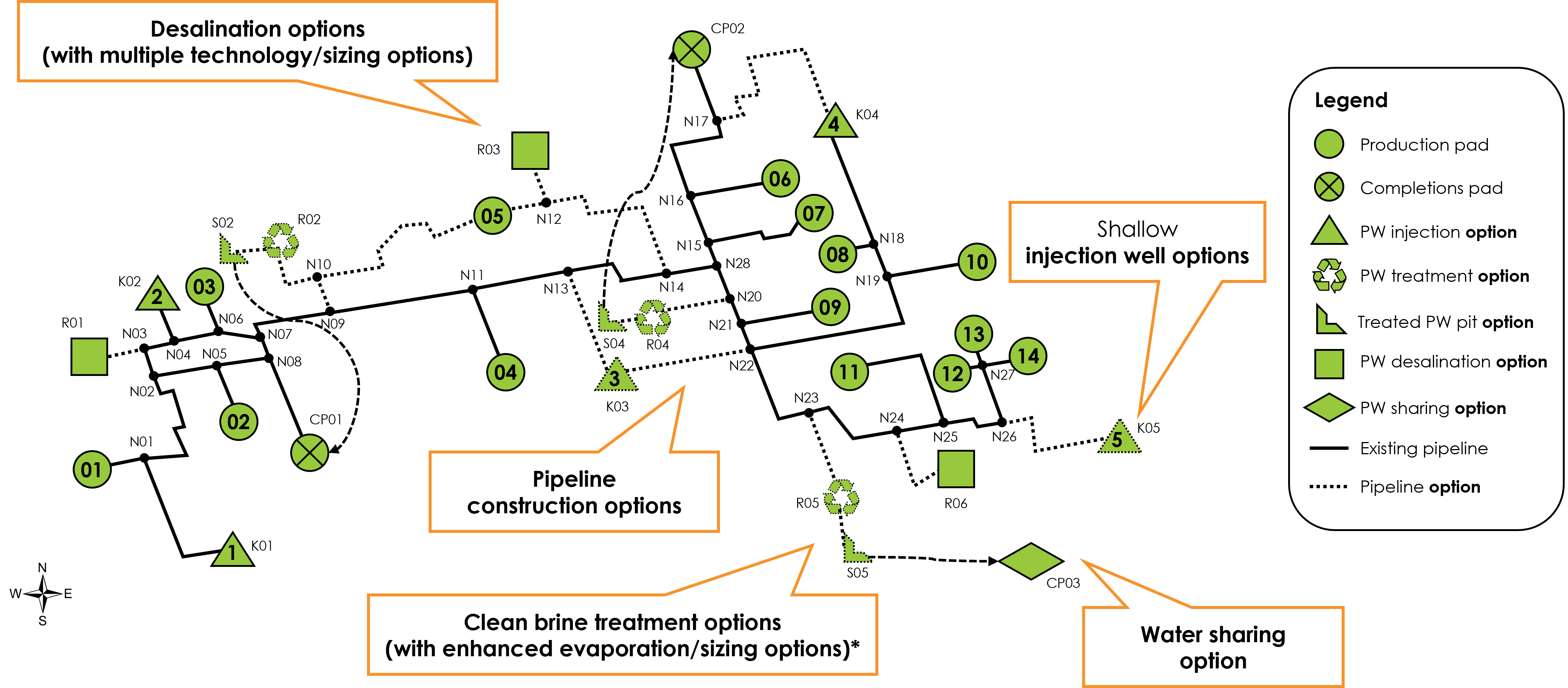

Strategic Permian demo network.

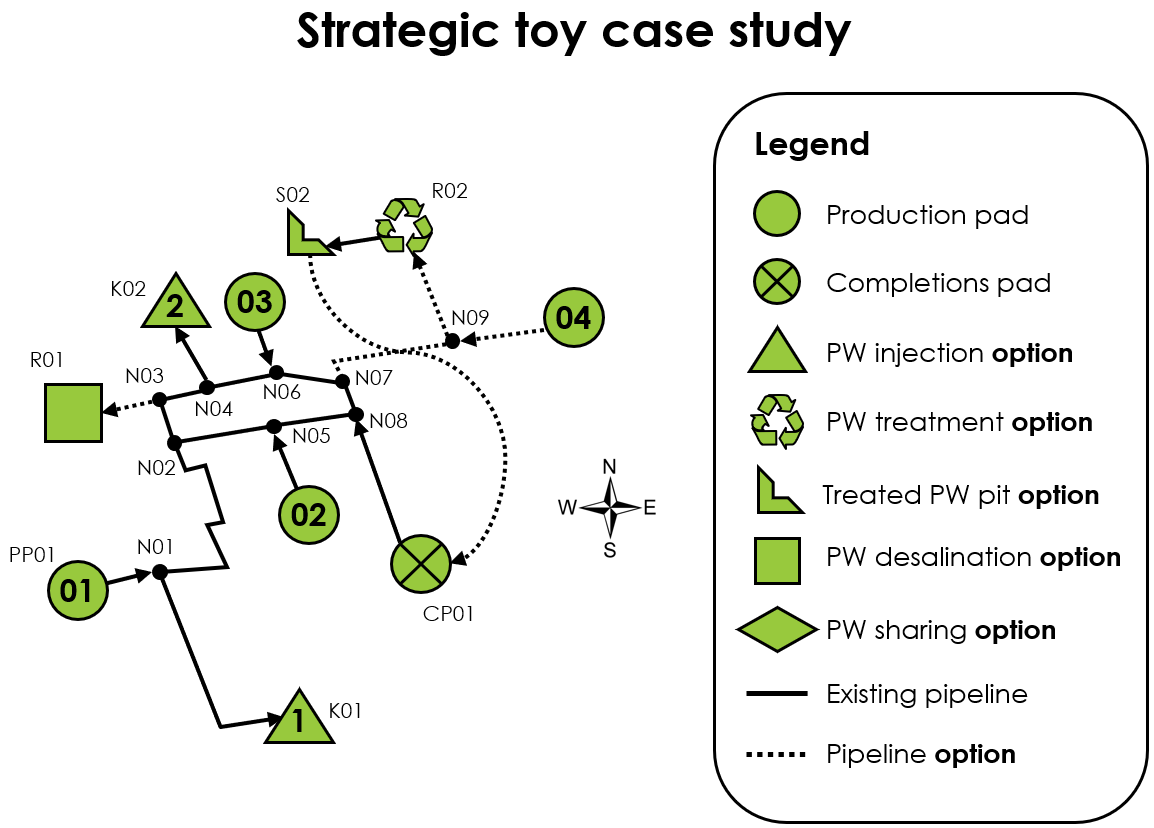

Strategic toy case study network.

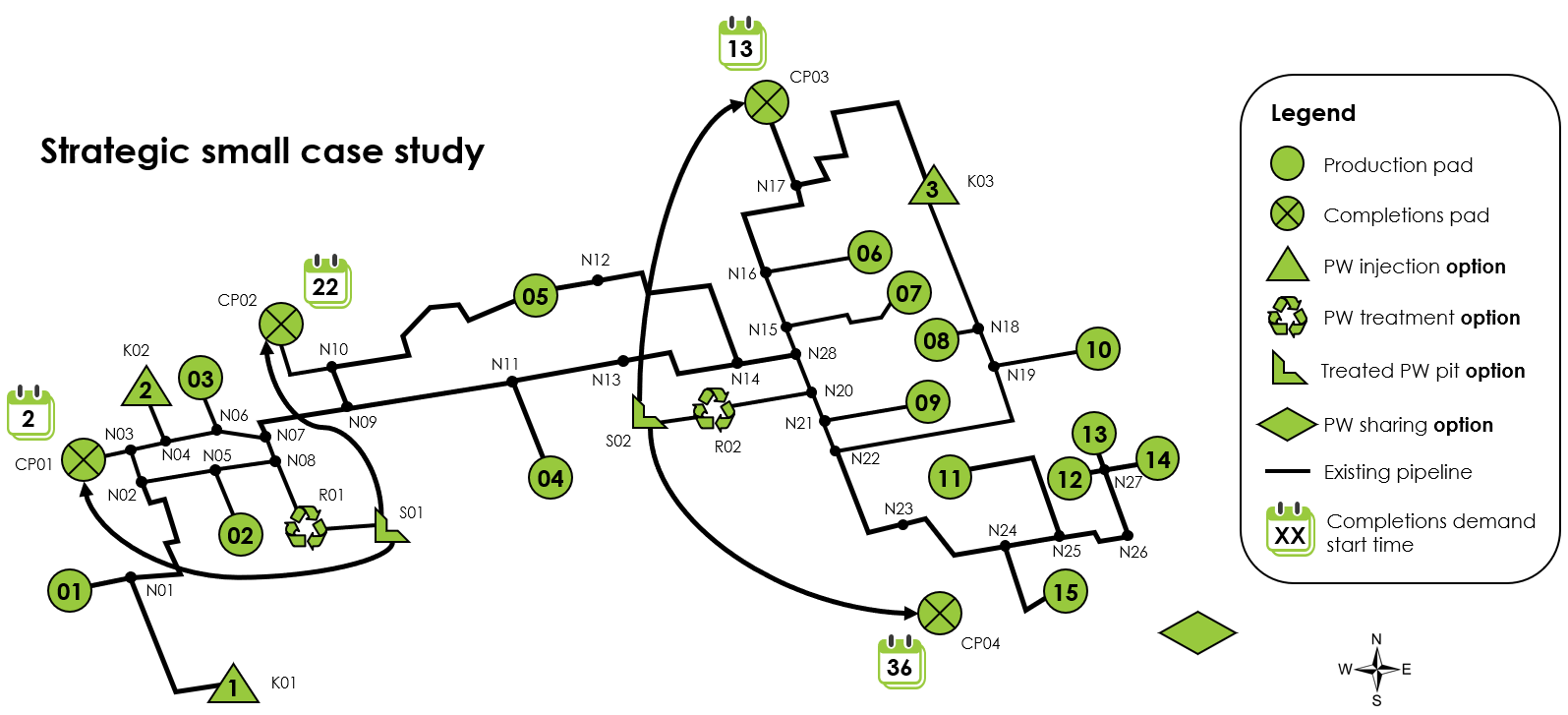

Strategic small case study network.

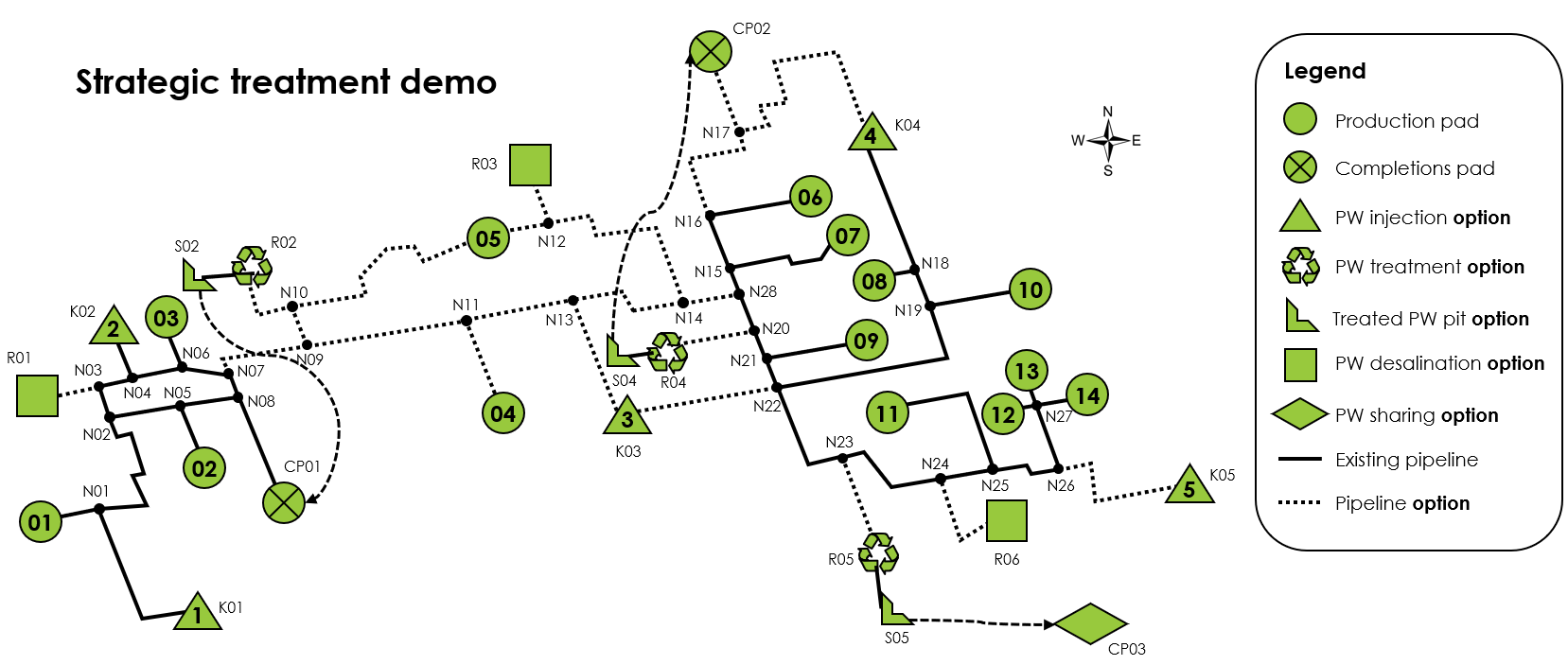

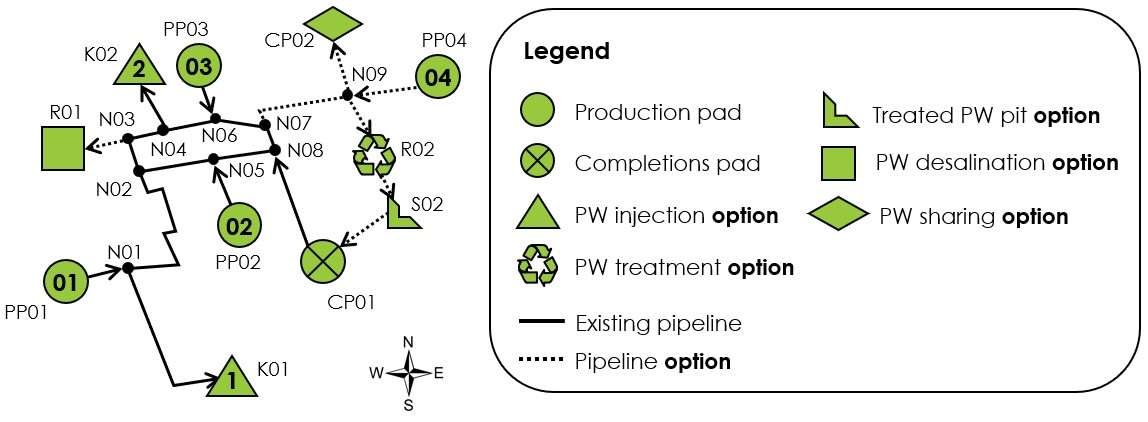

Strategic treatment demo network.

Strategic model network developed for use in PARETO workshops.

Comparison table

Strategic model Permian demo |

Strategic model toy case study |

Strategic model small case study |

Strategic model treatment demo |

Strategic model workshop baseline |

Operational model case study |

|

|---|---|---|---|---|---|---|

Input file |

|

|

|

|

|

|

Model type |

Strategic |

Strategic |

Strategic |

Strategic |

Strategic |

Operational |

Description |

A representative example of a |

A very small, toy-sized network. |

Larger network, but “small” in the |

Larger network, and disposal and |

Network developed for use in |

Generic case study for the |

Decision period |

Week |

Week |

Week |

Week |

Week |

Day |

Decision horizon |

52 weeks |

52 weeks |

52 weeks |

52 weeks |

52 weeks |

5 days |

Network nodes |

28 |

9 |

28 |

28 |

9 |

0 |

Production pads |

14 |

4 |

15 |

14 |

4 |

5 |

Production tanks |

N/A |

N/A |

N/A |

N/A |

N/A |

14 |

Completions pads |

3 |

1 |

4 |

3 |

2 |

1 |

External completions pads [1] |

1 (CP03) |

0 |

0 |

1 (CP03) |

1 (CP02) |

N/A |

Disposal sites (SWD) |

5 |

2 |

3 |

5 |

2 |

2 |

Disposal expansion allowed? [2] |

Yes, for K03 and K05 |

No |

No |

Yes, for K03 and K05 |

Yes |

No |

Storage sites |

3 |

1 |

2 |

3 |

3 |

0 |

Storage expansion allowed? |

Yes |

Yes |

No |

Yes |

Yes |

No |

Completions pad storage? |

No |

No |

Yes |

No |

Yes |

Yes |

Treatment sites |

6 |

2 |

2 |

6 |

2 |

2 |

Treatment technologies |

Non-desalination: CB, CB-EV |

Non-desalination: CB, CB-EV |

Non-desalination: CB |

Non-desalination: CB, CB-EV |

Non-desalination: CB, CB-EV |

N/A |

Treatment expansion allowed? |

Yes, except for R01 |

Yes |

Yes (but only one capacity option) |

Yes |

Yes |

No |

Pipeline expansion allowed? |

Yes |

Yes |

No |

Yes |

Yes |

No |

Hydraulics settings |

Roughness factor: 110 |

Roughness factor: 110 |

Roughness factor: 110 |

Roughness factor: 110 |

Roughness factor: 110 |

N/A |

Economics |

Discount rate: 8% |

Discount rate: 8% |

Discount rate: 8% |

Discount rate: 8% |

Discount rate: 8% |

N/A |

Notes |

Recommend solving with Gurobi, |

Recommend solving with Gurobi. |

Abbreviations

CB: Clean brine treatment

CB-EV: Clean brine treatment with enhanced evaporation

FF: Falling film evaporation

HDH: Humidification-dehumidification

MD: Membrane distillation

MVC: Mechanical vapor compression

OARO: Osmotically assisted reverse osmosis

SWD: Salt water disposal